foran_object

Monday, September 11, 2006

Sunday September 10: Travel to

Apparantly this guy doesn't like airport security much either. I'm surprised he got off so easy.

Saturday September 9: Things are at a stand-still

Problem is they are expensive, to the tune of 25$ each. I need professional help. If I unnecessarily spend money, I might as well get it professionally built. Somebody help me!!!

Friday September 8: An easy day goes bad

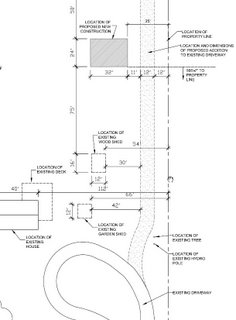

Today was supposed to be devoted to obtaining the concrete tubes (sonotubes), the plastic footing bases, and the various lumber to brace the tubes for the pour.

Frank B. was kind enough to offer the use of his truck to carry the materials home. Eric N. says I’d have no luck at all if it wasn’t for bad luck. Just as Frank arrives the sky opens and the fiercest rain storm I’ve seen in years comes down. Bernie and Ann's tree split and did substantial damage to their deck. The concrete tubes are made of cardboard, and seem to me to be flimsy enough as it is. Even thought they are coated with a bit of wax, I didn’t feel that traveling 40 KM in the rain was going to be good for them.

We ended up bringing them home in my car, in two trips. Jen had to sit at Rona because we couldn’t fit her into the car with the tubes. Again my luck hit. Traffic lights were out, and the traffic was so bad it took hours. Big thanks to Jen for her patience, tolerance and understanding. Not traits she exhibits on a day to day basis, but she brings them out when it really counts. I love you dear!

Thursday September 7: The excavator cometh

- Push top soil and organic material off the surface (~140 ft x 20 ft area)

- Dig trench for hydro line (150 ft x 1 ft wide x 3 ft deep)

- Remove stumps from the workshop footprint, and grade the soil

- Dig 20, 5 ft deep holes for the concrete piers that the building will rest on

My best guess was that this was going to take about two days. Battlefield wanted 2 x 330$ + 250 delivery + possible extra insurance charges because they would consider me to be somewhat of a high risk renter. Overall 1000+ dollars.

I decided to explore other options and called Tackaberry, a local aggregates and excavation company. They came out and recommended bringing a “highhoe” which is an excavator quite a bit bigger than a backhoe. The highhoe is 100$/hr vs. 70$/hr for the backhoe, both including operator. The highhoe can do trenching, excavation, etc much faster, usually resulting in a lesser price.

With a professional operator, and a bigger machine, the thinking was a single day should be plenty, and would cost about the same as me renting, with less risk. Highhoe we go.

Well, the day was quite stressful. Things go very fast with a machine this big, and good communication with the operator is key. Since I have pretty much zero experience with this type of work there were some mistakes. First, my plan was to forget about the hydro trench because the bigger machine was going to dig a really big trench which was going to require much more hydro sand fill, which is expensive stuff, also, there was the issue of needing to backfill part of the trench so that the trucks could bring in the gravel for the road and for the building. It ended up that we dug part of it, and that had me scrambling driving frantically to the local building supply store to get the electrical conduit and get it glued up in the trench so that we could backfill. All this time Bill the operator was essentially performing whatever he thought needed to be done.

The real problem came about from the fact that the big excavator has a 4 ft wide bucket. I had originally hoped to scoop out holes about 3 ft square with the backhoe. Bill recommended that the bigger machine would be better off digging big trenches instead. This was a last minute decision. When deciding to go with the highhoe instead of the backhoe, I had never considered the bigger bucket. I thought about it quickly, and didn’t see any problem. The excavation however is gigantic. Totally unnecessary for a building like I am putting up. This excavation is more suited to a house.

I freaked out (quietly). I even considered asking them to fill in the hole. I made some quick calls for advice. Big thanks to Scott J. for getting me some advice from his brother in law, John, who is a skilled contractor. The hole stayed and will be fine. Only this is that I spent more money than necessary digging it, and that it will cost about 1000$ more than I planned to backfill. More material, plus I’ll probably need to bring machinery back in. 8000 cubic feet of fill isn’t going to get put back in with a shovel.

Oh well, all in all, things have moved forward, and it’s not a disaster. I have come to the sad realization however, that I really do need professional help. Not for the actual labour, but for the expertise. Researching, thinking, and carefully planning don’t make up for actual experience.

Wednesday September 6: Clearing Brush

morrow the excavator and the aggregate come.

morrow the excavator and the aggregate come.

Archives

July 2006 August 2006 September 2006 October 2006 November 2006 December 2006 January 2007 February 2007 March 2007 April 2007 May 2007 June 2007 July 2007 October 2007 January 2008 January 2009 February 2009 March 2009